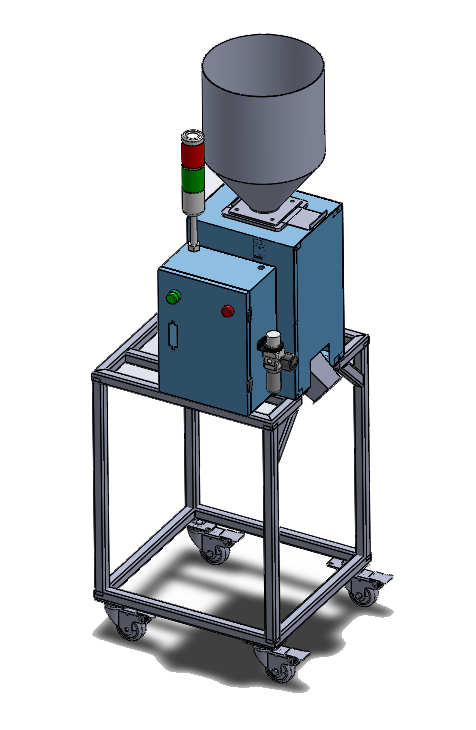

CYLINDER FOR INJECTION MOLDING MACHINE

We produce Cylinder by the latest advanced technologies to ensure the compatibility of components throughout the customer's continuous production process. This results in the creation of plastic products and plastic components for various industries and devices such as aerospace, medical, automotive, motorcycles, electronics, and household appliances.

1. Structure of Injection Molding Machine Cylinder

- The cylinder is typically a long tubular structure with a continuous central bore designed to accommodate the screw and screw head assembly.

- A hole is machined into the body of the cylinder for mounting the hopper, allowing plastic material to be fed into the cylinder.

- The cylinder body has holes for mounting temperature sensors.

- The outer surface of the cylinder is equipped with heating elements to melt the plastic material.

- The cylinder is made from high-pressure and high-force resistant materials such as alloy steel, and it is designed to ensure durability and precision during operation.

- The cylinder is divided into two material sections, each serving a different purpose.

- The outer shell: Made of a high-ductility alloy that can withstand high pressure.

- The core: Made of a high-hardness alloy, resistant to wear and corrosion.

- The thickness of the core ranges from 1.8 to 3.0 mm, depending on the diameter size.

- Cylinder also has other names such as Cylinder, Barrel,..

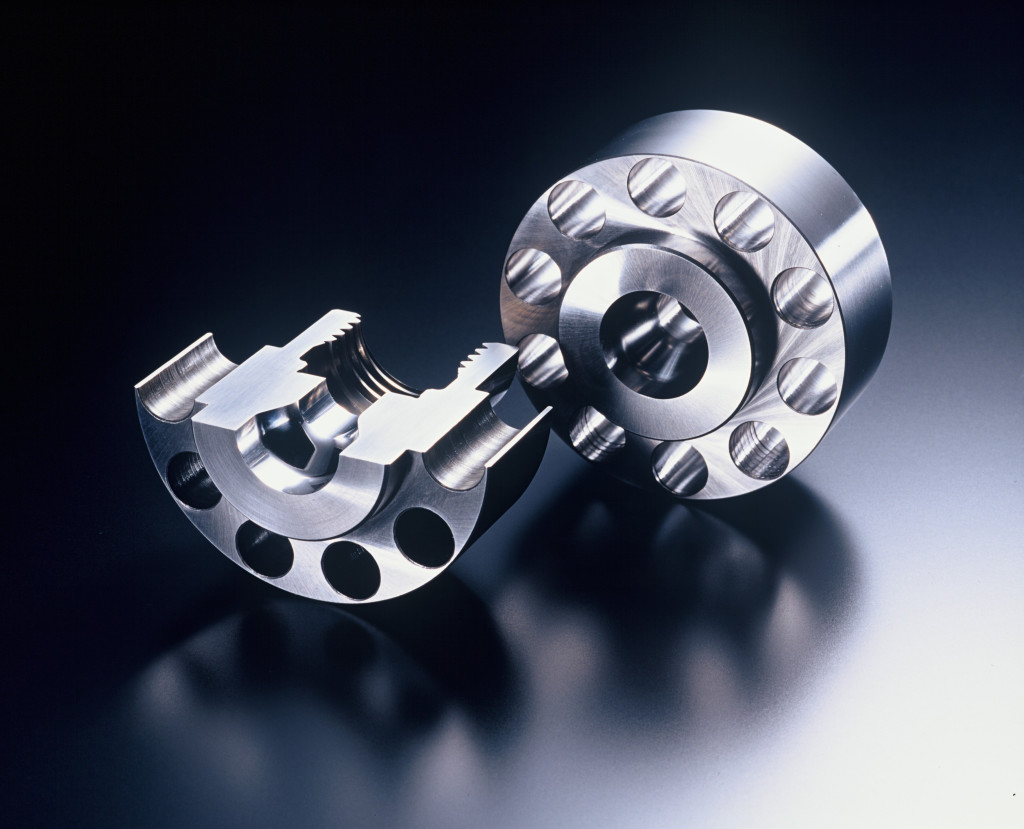

An image of the cylinder cut in half would clearly show the alloy coating inside the bore.

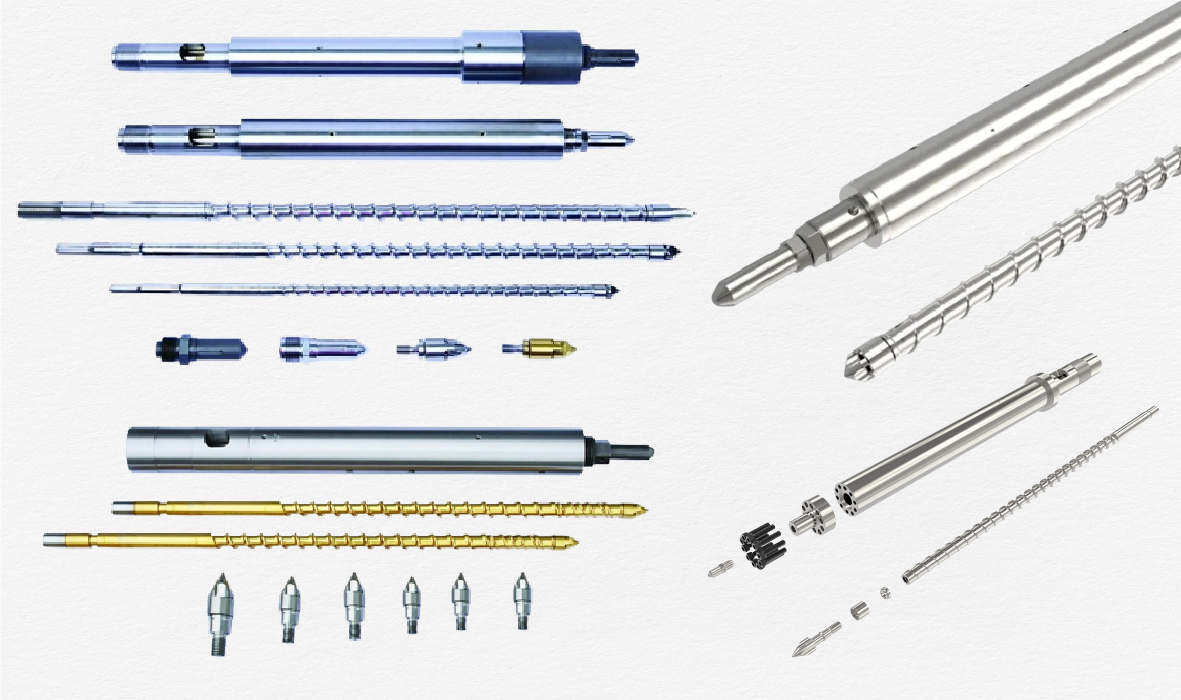

2. Manufacturing range

- Diameter from: D12mm – D160mm

- Maximum length: 3000mm

3. Application

- Glass fiber content in resin 0%GF to 65%GF.

- The type of plastic that the customer uses

- Non-corrosive plastic: PET, PP, PC, ABS…

- Corrosive plastic: PA, PA6. PA9T, PPS, LCP…

- High-viscosity transparent plastic: clear PC, colored PC.

- High hardness plastic: Bakelite.

4. Manufacturing method

2.1. Centrifugal Cast Cylinder

- Phương pháp này sử dụng bột hợp kim cho vào ống xi lanh , sau đó gia nhiệt và quay ly tâm với tốc độ cao để sử dụng lực ly tâm tạo ra lớp phủ hợp kim bên trong xi lanh.

- Đối với những loại nhựa khác nhau chúng tôi sử dụng lớp phủ hợp kim khác nhau.

- Đặc biệt là nhựa có chứa halogen, ASG sử dụng vật liệu siêu chống ăn mòn và mài mòn, tăng tuổi thọ của xylanh lên đáng kể.

2.2. Hot Core Injection Cylinder

- The cylinder shell is made of alloy steel.

- The core is made of reinforced alloy steel.

- The core is made using sintering technology (Hot Isostatic Press - HIP).

- The hot pressing is applied to bond the core to the cylinder shell.

Due to the superior properties of sintered materials compared to conventional ones, this type of cylinder offers excellent resistance to corrosion and wear. 4o

3. Product supply process

Step 1: Please send us a quote request including the following information:

- Full model name or model photo

- Component diameter and length specifications.

- Use plastic models or plastic packaging photos to select appropriate materials and component manufacturing technology.

Step 2 ASG Vietnam sends quotation to you.

Step 3: Customer send order.

Step 4: In most cases we have manufacturing drawings, in some cases we do not have drawings, we will come to your factory to measure and create drawings.

Bước 5: Production and product quality control according to ISO 9001:2005 standards

Bước 6: Delivery

Bước 7: Payment of order value.

3. Warranty policy

1 year warranty for all components

ASG screw cylinder – quality creates trust